Denny Hamlinwas sitting atop the velocity charts after 30 laps of the early afternoon Cup follow at Martinsville Speedway. However his day shortly went bitter when a bit of rubber jammed his throttle open, and in an effort to scrub velocity from the automotive, he turned the steering wheel, sending his automotive crashing backwards into the wall. As quickly because the TV announcers noticed the numerous injury to the proper rear, they concluded that the No. 11 crew would wish to tug out a backup automotive. Chris Gabehart, crew chief of the No. 11, and his crew at Joe Gibbs Racing, although, had a special thought. They introduced in NASCAR’s Hawk-eye Optical Scanning Station (OSS) to guage the injury — serving to them restore a presumed-totaled automotive in mere hours.

This is how they did it.

1:20pm, Saturday

Joe Gibbs Racing personnel and NASCAR officers start analyzing the broken No. 11 automotive. Gabehart was clearly disillusioned to see such a quick automotive in disrepair, however didn’t hesitate in working together with his group to start out chopping off broken panels. It took solely quarter-hour to take away the trunk lid and rear bumper, and expose the broken rear bumper helps. Preliminary observations revealed that the rear bumper helps had crumpled, which meant they’d completed their job to not solely defend the motive force, but additionally assist stop injury to the rear clip and gasoline cell.

A NASCAR official observes the No. 11 crew and automotive whereas the OSS completes its scans.

Picture by: Bozi Tatarevic

1:50pm

Mechanics from 23XI Racing joined their Joe Gibbs Racing counterparts to disassemble the rear of the automotive as shortly as doable, and begin getting ready the automotive for the OSS. The OSS makes use of structured mild scanning to measure bodywork and suspension right down to a tolerance of 0.150 inches and whereas it’s sometimes utilized for scrutineering functions, NASCAR can even open it as much as groups in particular conditions like this to see how far a automotive has shifted from its unique measurements. As soon as a scan is full, a warmth map is generated evaluating the bodywork to a CAD picture of the automotive that’s saved within the system together with an alignment sheet exhibiting measurements like camber and toe, very similar to you’d see for a avenue automotive.

Denny Hamlin takes a have a look at the injury on the No. 11 whereas JGR and 23XI crew members proceed to disassemble the automotive.

Picture by: Bozi Tatarevic

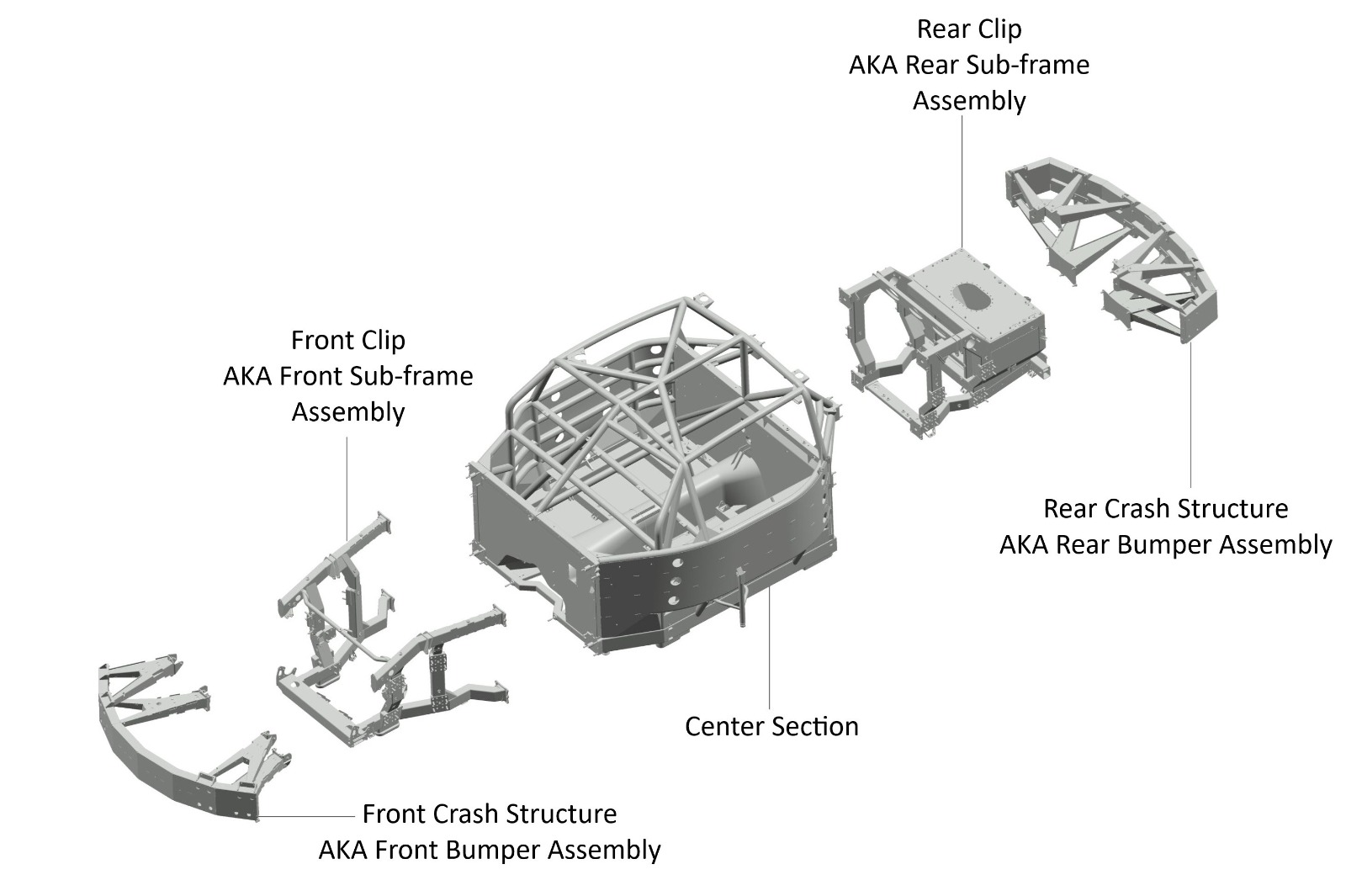

The chance to even contemplate these kinds of repairs is made doable by the modular nature of the NASCAR Subsequent Gen automotive, which permits the chassis and bodywork to be assembled and disassembled in items. The earlier technology automotive had a one-piece body, so when incidents like this one occurred, it sometimes meant going to a backup automotive as a restore would necessitate chopping and welding of the structural tubing.

Picture by: NASCAR

As a result of the Subsequent Gen chassis is constructed round a middle part which is a security cell for the motive force that then has a entrance clip and rear clip bolted to it. These clips then have bumper helps which can be bolted to them that act as crumple zones for the automotive. The middle part has 4 factors beneath it which can be used as reference factors for the OSS scans. Within the case of the No. 11, they had been capable of unbolt the broken rear bumper help construction and unbolt the broken bodywork, then shortly scan the remainder of the parts to check them to their earlier measurements.

2:00pm

Crew members pushed the automotive over to the OSS. Fifteen minutes later, they had been again within the storage with a choice to start out repairs based mostly on what the measurements confirmed. A big yellow field appeared on the liftgate of certainly one of their vehicles, which mechanics swarmed to seize wanted parts like a brand new bumper help together with bodywork.

The crew of the No. 11 automotive walks a yellow compartment field on wheels to their storage.

Picture by: Bozi Tatarevic

One other serving to issue to the speedy restore was the storage field that was organized in a manner that made grabbing needed parts straightforward. The crew employs a 5S group methodology for labeling and sorting — which isn’t a shock contemplating that Joe Gibbs Racing runs Toyotas and 5S is a part of Toyota’s Kaizen philosophy.

Three Hours Later…

Elements had been bolted to the automotive and the No. 11 crew was setting wheels right down to the bottom for one more run by way of the OSS to examine their repairs. The now repaired automotive was in the identical window as what it had proven throughout an earlier inspection. They introduced it again to the storage for some tweaks to the proper rear nook in an effort to get it to as close to excellent as doable.

6:30pm

The automotive was again on the bottom and pushed outdoors to check the engine, in addition to confirm that the throttle physique wouldn’t have any further points. After testing, and pleased with the measurements and look of the automotive, the No. 11 crew put it away for the evening.

Race day, Sunday

Hamlin’s automotive goes again by way of the OSS and the crew decides to make a few last tweaks earlier than pushing the automotive to the grid for the race.

Denny Hamlin, Joe Gibbs Racing, FedEx One Fee Toyota Camry

Picture by: Peter Casey – NKP – Motorsport Photographs

The modularity of the NASCAR Subsequent Gen automotive permits for parts to be transferred to a backup automotive pretty simply, however in essentially the most splendid conditions, utilizing the automotive you’ve spent weeks engaged on is at all times preferential. Within the case of the No. 11 automotive, the Subsequent Gen automotive was straightforward to deliver again to life after a big crash and allowed the crew to retain the automotive and velocity that they noticed in follow. And in reusing that quick major automotive, additionally they prevented an extended evening of driving over two hours to their store in Huntersville and spending ten to 12 hours engaged on a backup earlier than making the 2 hour journey again.

As an alternative, they had been capable of full a restore on the monitor in lower than 5 hours. Permitting the crew members to wrap up earlier than 7pm and be prepared and rested for race day. Sadly for Hamlin, he must begin the race in thirty seventh place. However he would make his manner into the highest 15 earlier than lap 100 and finally end the race in fifth place.